Alumina & Colloidal Silica

Highlights :

- Kemet Colloidal Silica and Alumina Suspensions use a combination of chemical-mechanical polishing actions, providing specimens with a deformation-free surface.

- This is produced by having a mixture of abrasive particles dispersed throughout a chemically aggressive liquid carrier.

- Usually having a particle size of between 0.05µm and 1 µm with a stabilized alkaline of pH of 9.5 or acidic pH of 3-3.5.

- It is also used for the final polishing of many materials such as, ceramics, composites and soft metals.

Category: Grinding & Polishing

Description

Kemet Colloidal Alumina :

- This is an acidic desperation Colloidal Alumina with a pH between 3 to 3.5.

- It can be used to provide a chemical mechanical polishing action, on materials such as germanium, silicon, sapphire and silicon carbide.

- Also used on pure metals providing low scatter finishes on nickel, tungsten copper, steel and aluminium.

- It can be used on most common laps and pads, but polyurethane and short nap cloths are recommended.

- Use either full strength or diluted 1:1 or higher with deionised water.

Selection Guide for Colloidal Alumina Suspension and Powder :

| Micron | Use | Size | Code |

| Alumina Suspensions for special applications | |||

| 0-1 | Steel & Hard metals | 1 litre | 600711 |

| 0-0.7 | Semi-hard metals | 1 litre | 600712 |

| 0-0.3 | Soft metals | 1 litre | 600713 |

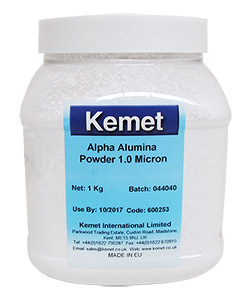

| Alumina Powder for polishing most materials | |||

| Gamma 0.04 | Superfinishing of soft metals such as copper, lead, aluminium | 1kg | 600251 |

| Alpha 0.3 | Final polishing of copper alloys, nickel, brass, bronze, aluminium | 1kg | 600252 |

| Alpha 1.0 | Fine pre-polishing of all metals | 1kg | 600253 |

Kemet Colloidal Silica :

- On ceramics and minerals the Colloidal Silica electrochemically attacks the surface to form a thin reactive layer on the specimen surface.

- This reacted layer can then be removed via the mechanical action of the cloth or abrasive.

- Compared with straight mechanical abrasives polishing, finishes are far better with Colloidal Silica.

- The chemical reaction is exothermic, so this action can be increased by raising the temperature. This can be achieved by increasing the polishing pressure.

- It can be used on polyurethane, short nap cloths and dense low-napped silk.

- Either full strength or diluted 1:1 or higher with deionised water.

- In application, wet the polishing cloth with distilled water, then slowly drip or spray the Suspension onto the polishing cloth. Then finally, for about 10 seconds before you finish polishing, apply water continuously to remove fine particles, which are electro-statically attracted to the specimen.

Selection Guide for Colloidal Silica :

| Micron | Use | Size | Code |

| 0.06 | Final Polishing Stage | 1 litres | 600261 |

| 0.06 | Final Polishing Stage | 5 litres | 600199 |

| 0.06 | Final Polishing Stage | 20 litres | 600202 |

Kemox SF – Aluminium Oxide Suspension Treated (Special Purpose) :

- Extremely strict selection process for particle size, shape and hardness to ensure maximum polishing performance over an extended life cycle

- Superior surface finish

- Excellent stock removal rate

- Easy clean up

- Long life

- Low viscosity to promote improved flow for polishing materials