Twin Chamber – Floor Standing Vacuum Packaging

Twin-chamber machines are mobile, plug-in units.

Thanks to the layout with two vacuum chambers, very high packaging outputs are possible.

Whilst the packaging cycle is running automatically in one chamber, the second chamber can be re-loaded..

Description

Why Twin Chambers ?

- Fast operation cycles,

- Powerful vacuuming pump,

- Excellent throughput,

- Large chamber and sealing sizes,

- Serves purpose of high volume and larger product sizes,

- Mobile, plugin devices,

- Easy to clean and maintain.

What are the Benefits ?

Robust technology in a stylish design

Our machines fit in well visually with any room layout thanks to their stylish yet pared-down design.

Precise sensors

Precise sensors for optimal shelf-life; simple adjustment for individual customer requirements.

Hygiene

Easy to clean, cable-free fastening of the sealing bars. No corners or recesses.

Optimal quality

Optimal quality thanks to the use of high-quality, perfected components – tested in continuous operation!

Custom-made solutions

We produce vacuum machines to the customer’s wishes in special sizes and special equipment variants.

Consultation

Personal consultation is at the core of our business. We attach particular importance to fairness and transparency.

Process reliability

Our control technology with program memory function permits reproduciblity and quality.

Support

Our service team is available by telephone or to visit your premises.

Service

Our easy-to-maintain design permits effective and simple care of your device.

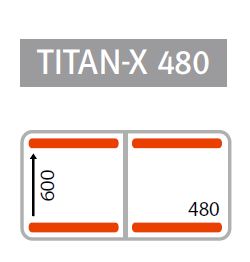

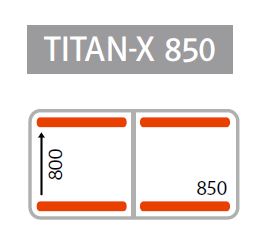

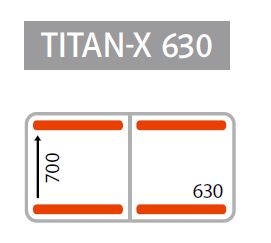

Specifications :

| Model | Sealing Bars |

Sealing Length(mm) | Pump (m3/h) |

Internal Dimension (mm) |

| TITAN X 480 | Dual | 480 | 63/ 100 | 610 X 760 X 200 |

| TITAN X 630 S | Dual | 630 | 63/ 100 / 160 | 740 X 660 X 230 |

| TITAN X 630 | Dual | 630 | 100/ 160 | 740 X 860 X 230 |

| TITAN X 850 | Dual | 850 | 160/ 250/ 300 | 960 X 960 X 230 |

| TITAN X 950 | Dual | 950 | 160/ 250/ 300 | 1060 X 860 X 230/280 |

Above specifications are in short. For detailed technical specifications reach us.

Upgrade Options :

- Gas flush device for protective gas atmosphere,

- Single or separately adjustable cut-off sealing,

- Top/bottom sealing ,

- Sealing bar can be independently switched on or off,

- Slow air release,

- Control at side on a stainless steel arm,

- Transparent panel in lid,

- Automatic lid shift,

- Special accessories.