Image Analysis Software for Metallurgical Inspection.

Highlights :

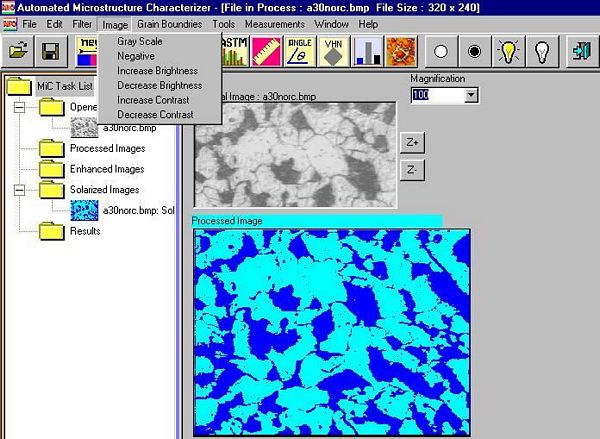

- Quantification of phases ( ASTM E566, ASTM 1245 ),

- Inclusions ( ASTM E454 / E1245 ),

- Grain Size ( ASTM E112 ),

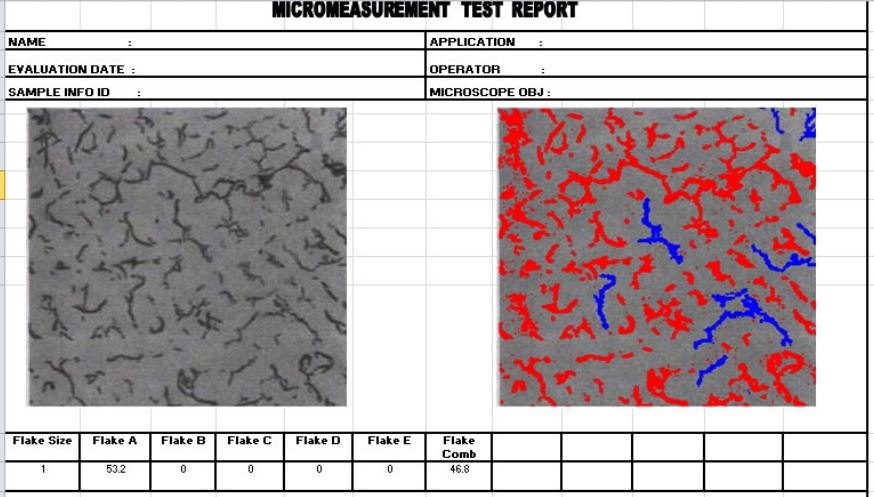

- Nodularity (ASTM A247),

- Porosity (ASTM A276),

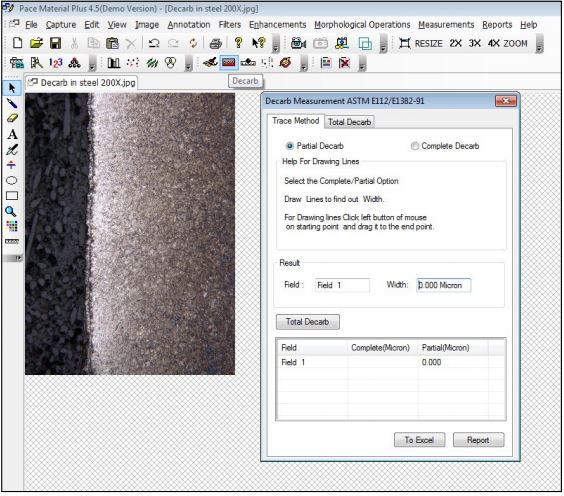

- Decarburization (ASTM E1077), &

- Coating thickness (ASTM B487)

Description

– Our range of Image analysis systems provides a single fully integrated analytical tool for study and documentation of microstructures using fast and automatic image processing techniques.

– The image analysis is achieved by capturing the picture through a high resolution color digital camera interfaced to the camera port of the metallurgical microscope.

– The image is imported onto a PC by a specially designed image acquisition card for preview and storage.

– Materials Plus module provides a customized report generator or reports can easily be exported to Microsoft Excel.

Measurements

Image Analysis

-Measurement tools: calibration, length, angle, perimeter, width, radius, area, circle, color, counting

Metallographic Tools

– Particle measurement,

– Segmentation,

-Grain size (Manual, Manual circle, Manual line, Comparison, Automatic circle, Automatic line, ALA, Selection),

– Decarburization,

– Nodularity,

– Flake,

– Coating thickness (Psuedo-color, Parallel-line, Trace, Selected Coating) ,

– Inclusion,

-Porosity (Porosity, Selected area)