Integral Easydur – Universal Hardness Tester

- Hardness according to EN-ISO and ASTM Standards DIN, on every type of metal and alloys, synthetic materials, ceramics, abrasive stones, plastics, rubbers, inert materials and many other materials.

- You can enter the loading forces for supplementary evidence on request.

- The instrument complies with the following standards:

- Brinell EN-ISO 6506 and ASTM E10;

- Vickers EN-ISO 6507 and ASTM E384;

- Rockwell EN-ISO 6508;

- Plastics DIN 53456;

- Knoop;

- It is possible to perform checks on metallographic structures of metal and perform measurements of the depth of the surface hardness treatment.

- It can be used in laboratories for quality control, production departments for quick tests, in research institutes, technical schools and universities.

Description

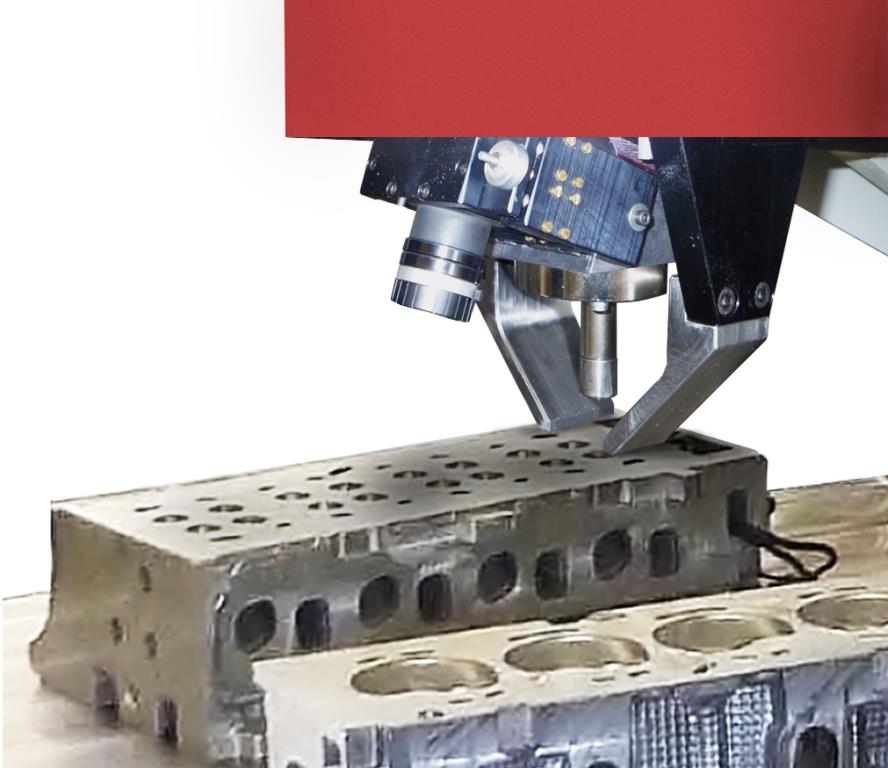

– Integral is a hardness tester for testing the hardness in Vickers, Rockwell, Brinell with fully automatic test cycles and camera for automatic recognition of fingerprints. Several models are available depending on the need The instrument on

– The instrument on request, can be configured as the primary machine, for the certification of the reference blocks.

– Integral is equipped with a motorized moving head.

– Integral allows to carry out tests quickly and fully automatic, all the phases of a test are handled by the instrument in total autonomy, from the search of the piece, to the test, until the release of the workpiece.

– The Measurement Camera: The instrument is equipped with a camera to detect Brinell and Vickers footprints, with wide range of magnifications and cameras on request. The advantages are:

- High resolution

- Auto focus

- Crisp even on coarse pieces Picture

- Electronic Image Management

- Printing images to metallographic examination

- Controls and dimensional measurements of the material surface

- Algorithms for turned parts

- Algorithms for ASTM and DIN ISO

- Algorithms for fingerprints ovalized